Chapter V – Roads, sandpits and forest infrastructures

Division III – Bridge, culverts, removable structures and rudimentary structures

§4. General provisions applicable to bridges or culverts

Section 99

The construction, improvement or repair of a bridge or a culvert must be carried out in a manner that ensures its stability and operation regardless of the period the work is carried out and the work methods used. The stabilization of the bridge or culvert must be done as the work progresses and any defect must be corrected as soon as it is detected.

The stabilization of the bridge or culvert must be done as the work progresses and any defect must be corrected as soon as it is detected.

1

Objectives

- To ensure the lifespan of a road, bridge or culvert

- To avoid carrying sediment into an aquatic, wetland or riparian environment

Additional information

Climate factors can cause technical problems during construction, improvement or repair work on a bridge or culvert. For example, winter work presents a number of challenges, mostly related to water management, compaction, stabilization of the structure and control of sediment inflows. Additional precautions are therefore needed in winter, compared to other seasons.

2

Objectives

- To ensure the lifespan of a road, bridge or culvert

- To avoid carrying sediment into an aquatic, wetland or riparian environment

The fill must be compacted in successive layers up to above the conduit or arch.

3

Objective

- To ensure the lifespan of a road, bridge or culvert

Additional information

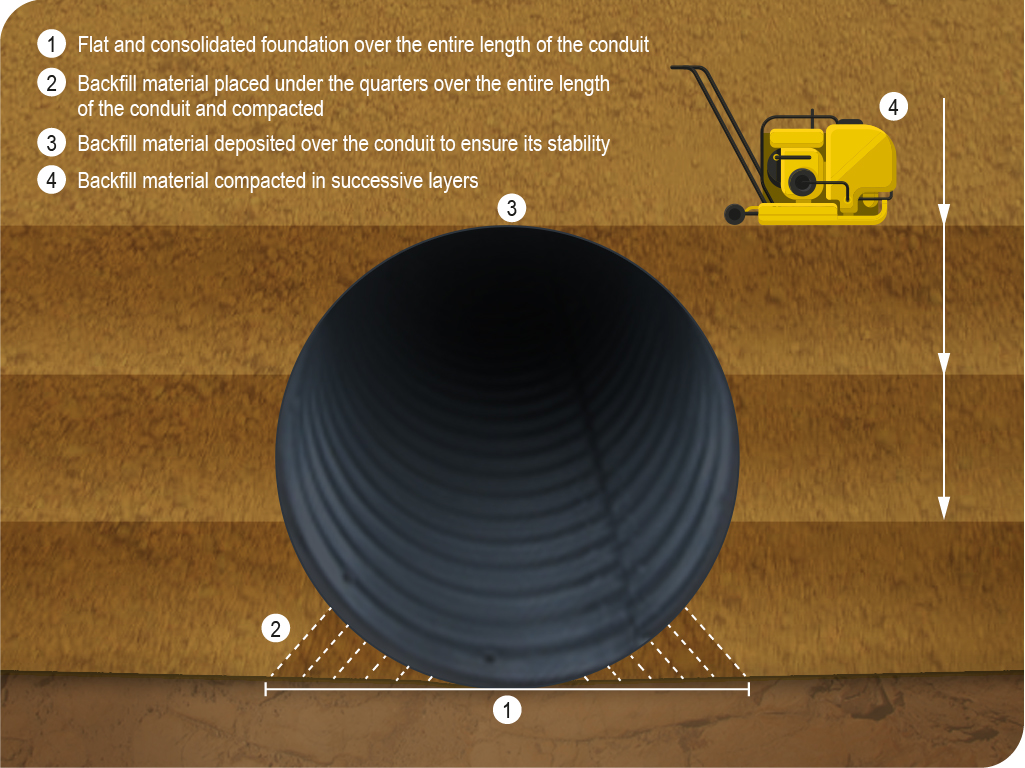

Preparation of the foundation and backfilling of a culvert or a wooden or non-wooden arch of a culvert are two crucial steps in ensuring the longevity of the structure and the safety of forest road network users. Note that a wooden culvert is a culvert with a wooden arch.

Preparation of the foundation

The conduit, the walls of a wooden culvert or the shoe of an arch other than a wooden arch must be installed on a flat foundation and must be consolidated over their full length.

If the base of the excavation is in sand or stone-free gravel, this is the ideal material for a foundation. On the other hand, if the base is composed of clay or organic matter, or if there are stones, a sufficient quantity of this material must be excavated and replaced with sand or gravel. In some situations, it is preferable to install a geotextile membrane first, to improve the load-bearing capacity of the foundation and avoid the possibility that the structure will sink under the weight of vehicles.

Backfilling

When the conduit or arch of the culvert is in place, it must be consolidated with backfill. This is an important step, since it will determine the culvert’s structural capacity. Arches and conduits are not particularly resistant to loads; it is the backfill material surrounding them that allows them to bear loads. Vehicles must not be allowed to drive over the conduit or arch until the backfill has reached the minimum thickness required by section 100.

The choice of materials for backfilling the conduit or arch, as well as its installation and compacting of the backfill are also important. The materials used must be of the same category as those used for the foundation, i.e. sand or stone-free gravel, to avoid deformation or perforation of the conduit or arch. In addition, these materials are easier to compact and improve the structure’s stability. They are deposited by means of a shovel, under the widest portion of the conduit or to the sides of the arch, and then they are compacted to ensure that there are no empty spaces. It is also preferable to deposit backfill material on top of the conduit to prevent it from lifting when the lower materials are compacted.

Backfill material must be present under the quarters along the entire length of the conduit to ensure its bearing capacity. It must be packed in such a way as to avoid empty spaces. Note that it is preferable to deposit backfill material on the conduit to prevent it from lifting when the materials placed under the quarters are compacted.

The filling of the conduit or arch is completed by depositing the material in layers of about 30 cm, compacted successively. The compaction must be carried out with a suitable device such as a vibratory plate compactor, a compacting pestle or a compacting roller. Each layer must be deposited and compacted equally, on both sides of the conduit or the arch. Proper compaction of the material prevents its deformation and ensures optimum bearing capacity and the durability of the culvert.

Backfilling of the conduit or arch is completed by depositing the materials in layers of roughly 30 cm and then compacting it using an appropriate device, such as a vibrating plate. Each layer must be laid and compacted equally, on either side of the conduit or arch. Proper compaction will help avoid distortion and will improve the culvert’s load-bearing capacity and longevity.

Figure 99 Backfilling of a conduit

To ensure the durability of the culvert, special measures must be taken to ensure compaction and an adequate stabilization when materials used are frozen.

4

Objectives

- To ensure the lifespan of a road, bridge or culvert

- To avoid carrying sediment into an aquatic, wetland or riparian environment

Every person authorized to build or improve a culvert who builds or improves the culvert from 15 December to 31 March must inspect the culvert after the spring flood and correct any defect within 7 days after the inspection. The foregoing also applies to a person who repairs a culvert during that period. The inspection must be carried out not later than 30 June following that period.

5

Objectives

- To ensure the lifespan of a road, bridge or culvert

- To avoid carrying sediment into an aquatic, wetland or riparian environment

Additional information

All anomalies identified outside the inspection period must be corrected as soon as they are identified, as indicated in the first paragraph of this section.

Considering the varying climatic realities that can change from one year to another and from one region to another, any person authorized to build or improve a culvert or any person who rebuilds a culvert during the period from 15 December to 31 March may file, with the management unit in charge ![]() (in French), a request for an exemption from the Regulation under section 40 of the Sustainable Forest Development Act to agree on different date than 30 June to complete the required culvert inspection and corrective actions.

(in French), a request for an exemption from the Regulation under section 40 of the Sustainable Forest Development Act to agree on different date than 30 June to complete the required culvert inspection and corrective actions.